+91 22 66109000 wondermesh@gmail.com

Product Range

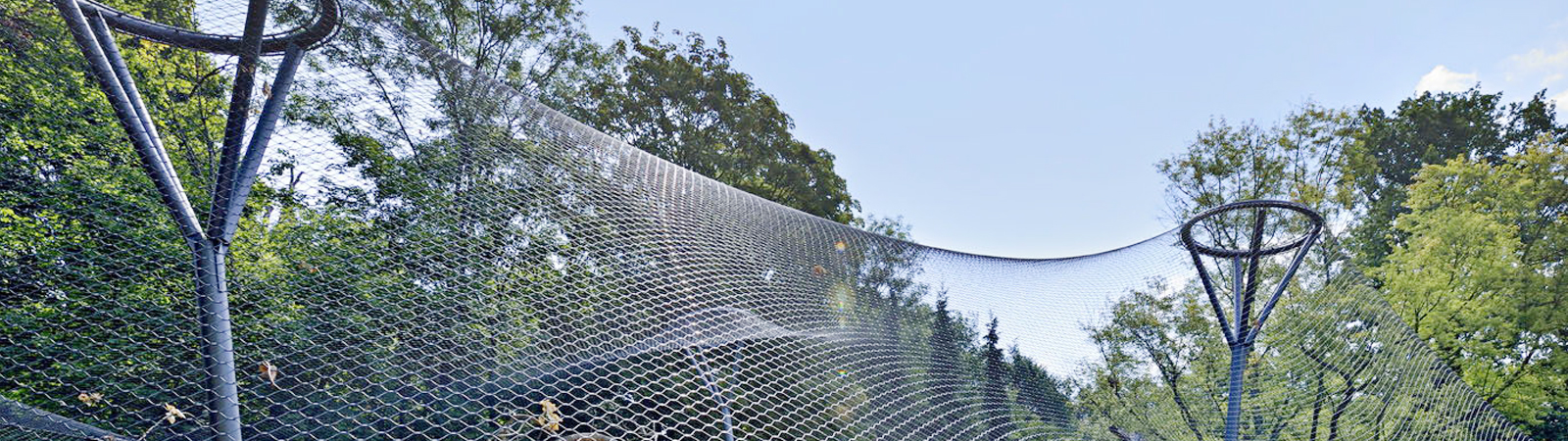

‘WONDERNET’ is a revolutionary product from the stable of ’WONDERMESH’ developed in time for the massive revamp of Indian Zoo & National Parks to preserve Wildlife in the most eco – sensitive manner.

The Present product line presented as ‘WONDERNET’ has the following characteristics and advantages over the conventional Crimped Mesh used under the current system.

- Very High Corrossion Resistance due to use of high-alloy stainless steel grade.

- 5x strength due to the use of wire – ropes instead of wire ensuring long life to the enclosures and added robustness to ensure visitor safety as well as Animal Welfare.

- Aesthetically appealing architecture with strength and appeal as the mainstream behind designing these ecological parks and Zoo.

Apart from manufacturing these state of the art Wondernet we can also provide the design engineering and installation for such prestigious projects.

Our structural calculations for the preassembled systems are done taking all load cases into account our statistical analysis services at a glance.

- System development

- Geometry of the stainless steel netting

- Calculation of cable and mesh loads

- Attachment force calculations.

- Verifiable structural calculations.

All of the above calculations are extremely important keeping in mind the structural tensile and dynamic loads that will be created by these nets installed on the super structures.No stone will be left unturned to ensure not only an aesthetically appealing National Park but also a quality installation will ensure that these beautiful systems shall last for atleast 50+ Years.

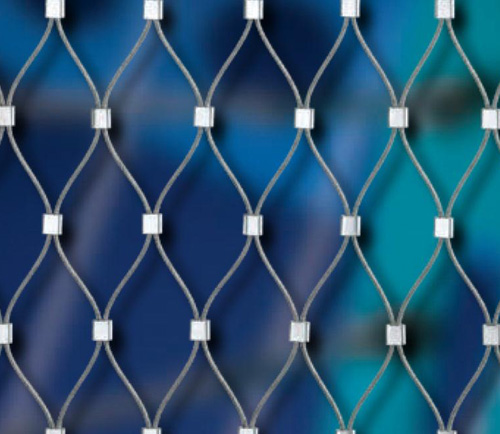

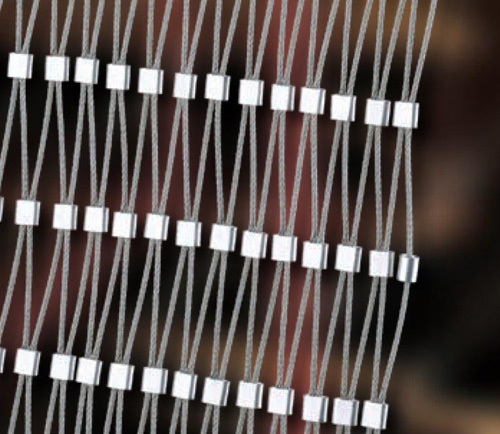

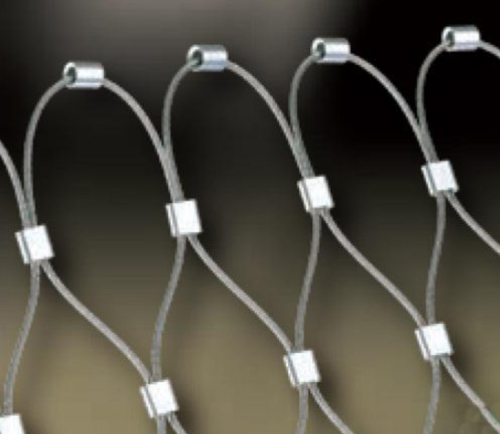

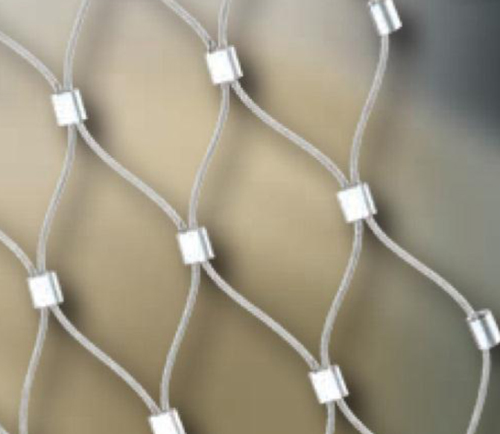

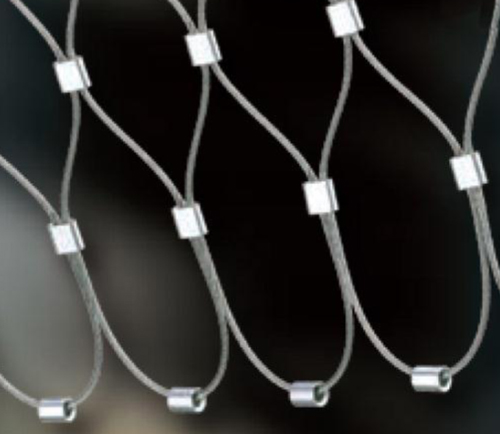

A fabric of particular Resilience and flexibility, a "net" whose strands are neither knotted nor crossed: Wondermesh wondernet is a construction based on stainless steel wire ropes that lie parallel in pairs connected and reciprocally curved by offset sleeves.

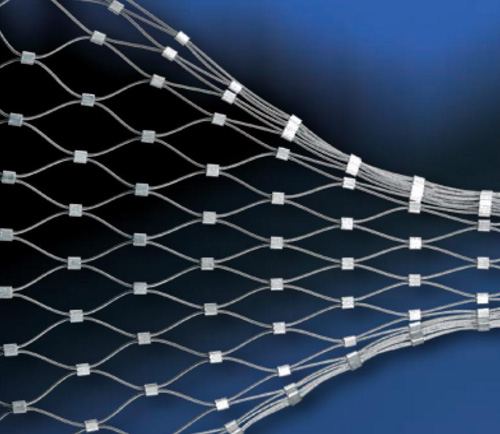

The net construction can be pulled apart like an accordion, producing a spring force that varies depending on the mesh aperture and wire-rope thickness.

Wondernet is a vibrant, premium-quality product: the mesh aperture (variable, from every tight to very wide) and the wire-rope diameter (1.0mm, 1.5mm, 2.0mm and 3.0mm) determine its functionality and aesthetics, most wondermesh Wondernet components are made from the AISI 316 material group.

Webnet with mesh aperture 40mm and wire-rope diameter 3.0mm

Webnet with mesh aperture 40mm and wire-rope diameter 2.0mm

Webnet with mesh aperture 40mm and wire-rope diameter 1.5mm

Webnet with mesh aperture 40mm and wire-rope diameter 1.0mm

Wondermesh Wondernet was tested pursuant to EN 1263-1 for its static and dynamic load-bearing capacity.

Test data:

- Webnet size: length 7 m x width 5 m

- Webnet rope 3.0 mm, mesh aperture 60 and 100 mm (horizontal and vertical meshes)

- Webnet rope 2.0 mm, mesh aperture 60 and 100 mm (horizontal and vertical meshes)

- Suspension rope 10.0 mm

- Test object: 500-mm steel sphere, mass 100kg

- Drop height of test object: 7 m

Webnet not tensioned (closed)

Webnet with 35o mesh angle

Webnet with 50o mesh angle

Webnet with 60o mesh angle

Wondermesh Wondernet has the skin-like characteristics of a diaphragm. It can form a plane surface but can also be tensioned into three-dimensional forms featuring funnel-type, cylindrical, or spherical shapes.

Wondermesh Wondernet the original:

- Custom - manufactured

- Filigreed, discreet, elegant, flexible

- Multifunctional, compatible with creative architecture

- Premium quality, rugged, weather-resistant, non-corroding

Selection criteria for perimeter configuration V1 to V30:

- Construction of periphery structure, such as suspension ropes (p. 30/31), tubular frame (p. 32/33), rod system (p. 34/35), or Webnet C rail (p. 37)

- Overall dimensions of Webnet

- Assembly-related reasons

- Magnitude of Webnet pretension forces

Some selection criteria for vertical (V) or horizontal (H) Webnet mesh orientation:

- Architectural considerations

- Vertical meshes are less suitable for climbing (safety factor load)

- Assembly - related reasons (tight radii always require vertical meshes)

- When the Webnet is tensioned, the forces are greater in the mesh height direction than in the mesh width direction.

Vertical mesh perimeter:

open at top wire-rope and pairs

Vertical mesh perimeter:

closed with uncompressed sleeves at top

Webnet V:

vertical mesh

Vertical mesh perimeter:

with uncompressed sleeves at right

Vertical mesh perimeter:

closed with uncompressed sleeves at bottom

Vertical mesh perimeter:

closed with Webnet eye ends sleeves at bottom

All Rights Reserved by Wondernet

Designed By Mirackle Solutions